Diagnostics

Diagnostics| You can access the diagnostics function from the home screen. |  |

| You must first be logged in as the Supervisor. |  |

This function is useful for fault-checking new tools. Once you have configured the controller for the new tool (i.e.: set the number of cavities and manifolds) the diagnostics function can be used to check that the new tool is wired correctly.

The diagnostics function will determine the following tool characteristics:

- Cross-wired zones, e.g.: Zone 1's heater wired to Zone 2's thermocouple.

- No-load heaters. This could be a blown fuse or an open-circuit fault. The heater resistance cannot be determined because of poor connections. It is possible that the heater itself is faulty.

- Open thermocouples. The two connections to the thermocouple do not make a circuit. The zone's temperature cannot be read in this case.

- Reversed thermocouples. The two connections to the zone's thermocouple are reversed. The zone's temperature reading is incorrect in this case.

- Heater resistance for each zone. This determines the maximum current drawn by the heater when it is at 100% power. It determines the power of the heater.

- The response of each zone to a set amount of power to it's heater.

The diagnostics function proceeds automatically without user intervention. However, some simple checks are carried out first to make sure that the results will be accurate.

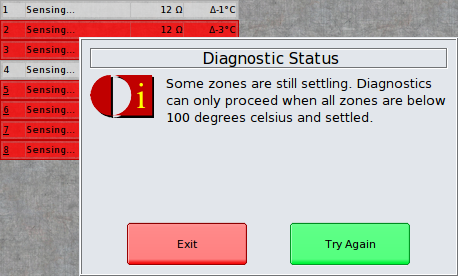

Diagnostics will not proceed unless the following conditions are met, these being checked automatically by the controller before diagnostics begins:

- All zones must be below 100 degrees celsius.

- All zones should be "settled". This means that they are not still cooling down particularly quickly.

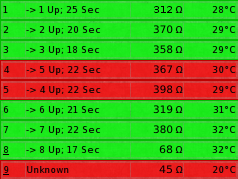

This

image shows that zone 1 has been tested already, that it is wired

correctly (->1), that the thermocouple is ok ("Up") and that it

took

25 seconds to change temperature by at least 6 degrees celsius.

Zone 2 is currently being tested.

This

image shows that zone 1 has been tested already, that it is wired

correctly (->1), that the thermocouple is ok ("Up") and that it

took

25 seconds to change temperature by at least 6 degrees celsius.

Zone 2 is currently being tested.For manifolds, a 6 degree change is expected within 240 seconds. The manifold being tested is energised at 60% power.

This

image shows a problem with zones 4, 5 and 9.

This

image shows a problem with zones 4, 5 and 9.Zones 4 and 5 are cross-wired (the thermocouples or heaters are connected in reversed order).

Zone 9 failed to respond, so 60% power was applied to this zone for 240 seconds and no thermocouple changed by 6 degrees celsius. It could be a "cold thermocouple", or perhaps the thermocouple is not seated correctly.

Once

all zones have been tested, diagnostics is ended and the user has the

option of saving the results in a text file stored on the controller.

This file can later be viewed

on the controller, or exported

and viewed on a PC.

Once

all zones have been tested, diagnostics is ended and the user has the

option of saving the results in a text file stored on the controller.

This file can later be viewed

on the controller, or exported

and viewed on a PC.